The DoD’s Opportunity

The Department of Defense’s (DoD) acquisition process is facing significant challenges in meeting the rapidly evolving demands of modern warfare. The traditional acquisition methods are often slow and cumbersome, resulting in delayed delivery of critical capabilities and increases costs. The complexity and interdependency of modern defense systems require a more integrated and holistic approach to design, development, verification, and sustainment.

The DoD is grappling with the need to keep pace with technological advancements and leverage cutting-edge innovations to maintain military superiority and outperform and outpace our adversaries. However, the current acquisition process often struggles to effectively incorporate emerging technologies, resulting in outdated systems that cannot adapt to evolving threats or take full advantage of breakthrough capabilities. Moreover, the DoD’s acquisition process lacks the necessary level of digitization and standardization, leading to fragmented data, communication gaps, and limited collaboration across stakeholders. This fragmented approach hampers the ability to make informed decisions, share critical information, and efficiently manage the entire lifecycle of defense systems.

There is a pressing need for the implementation of Digital Engineering principles within the DoD’s acquisition process. Digital Engineering, as outlined in the DoD Digital Engineering Strategy, offers a transformative solution to address these challenges. The DoD Digital Engineering Strategy emphasizes the use of digital models, simulations, and data-driven decision-making to enhance acquisition practices and improve system performance throughout the lifecycle. Ultimately, Systems Engineering and Integration (SE&I) still has the fundamental processes; that is, Requirements Analysis with Use Cases and environments to capture, validate and refine requirements. A Functional Solution is still developed, decomposing requirements, defining of a Functional Architecture with flow down of performance and functional interfaces. Moreover, a Physical Solution is still developed, whereby we define alternative system physical concepts, configuration items, and system elements. The evaluation of alternatives and selection of the most effective alternative employing optimization is still performed. So, what is different?

The difference is that document-based SE&I or traditional SE is focused on the generation of textual specifications and design documents. Hardcopy or electronic files are the basis of exchange between the user, developer, and tester. System requirements are expressed in documents containing textual descriptions, graphical depictions generated from CAD, drawing tools, and tabular data. This results in diverse models and analyses from a variety of engineering groups whose data is not integrated. Our observation has been that the emphasis is on controlling the documentation, ensuring its validity, completeness, consistency, and compliance. Whereas, with Digital Engineering, the primary artifact is a coherent model of the system or systems of systems. A collaborative deliberative environment allows engineering teams to unify their analytical efforts around a key data aspect and the creation of the authoritative sources of truth (ASoT).

By leveraging advanced modeling & simulation tools, Digital Engineering enables a more efficient, agile, and cost-effective approach to the design, development, and sustainment of defense systems. It promotes early identification and mitigation of risks, enables virtual prototyping, facilitates collaboration among stakeholders, and improves the overall decision-making process.

It is crucial to address the challenges of the DoD’s acquisition process by embracing Digital Engineering principles and fostering a digital transformation in line with the DoD Digital Engineering Strategy. This will ensure timely, cost-effective delivery of cutting-edge defense capabilities that can adapt to emerging threats and technological advancements, ultimately enhancing the effectiveness and readiness of our warfighters.

We are industry leaders in Digital Engineering tradecraft and have deployed and applied Digital Engineering practices to the DoD’s most complex systems.

Our Solution—Parsons Digital Engineering Framework (PDEF)

We apply Digital Engineering (DE) to every aspect of the system acquisition process—including design, engineering, software, manufacturing, testing, and sustainment efforts—resulting in high-speed innovation, reduced risks, reduced program costs, and accelerated delivery. This is accomplished via a multidisciplinary approach, integrating Model-Based Systems Engineering (MBSE), Digital Engineering, Agile processes, and an open architecture tailored to the DoD’s Modular Open Systems Approach (MOSA), Sensor Open Systems Architecture (SOSA), Weapon Systems Open Architecture (WOSA), and Modular Open Radio Frequency Architecture (MORA). We implement a Digital Ecosystem through the Parsons Digital Engineering Framework (PDEF).

PDEF provides the capability for accelerated, technically credible analytics, and fast and agile prototyping, supporting the rapid transition of capabilities from the laboratory to the warfighter. PDEF is an innovative tool suite of MBSE and Modeling and Simulation tools, which can be any mix of COTS/GOTS and/or customer-derived tools, as required. The mix of tools in the suite is tailored to the needs of each customer project, providing optimal and cost-effective use of resources. The PDEF approach yields:

- Requirements digitally traced to design, analysis, and verification

- Structural models illustrating the principal system components and their interfaces

- Component characteristics represented by physics-based models

- Behavioral models describing user operations, system performance, and insight into operational constraints

- Seamless integration with the entire lifecycle from initial conceptualization through development, testing, deployment, and maintenance ensuring consistency at every stage

- Substantial support during acquisition by facilitating clear communication between stakeholders, enabling detailed requirements definition, and visual representation of system components

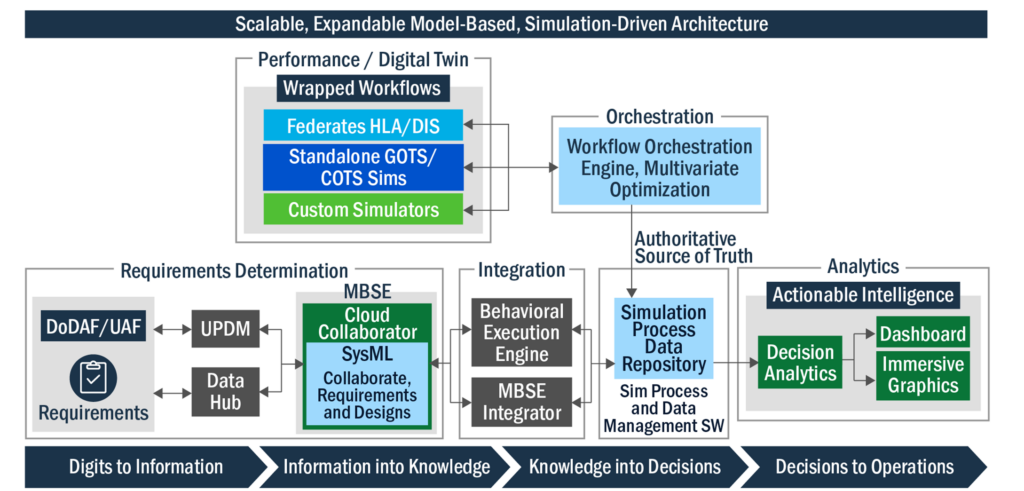

The digital engineering architecture shown below in Figure 1 illustrates the PDEF approach which supports rapid requirements and functional analysis leading to a comprehensive design synthesis. The tool-agnostic PDEF enterprise architecture leverages Commercial-Off-The-Shelf (COTS) simulation, optimization, reporting, visualization, and graphical tools to establish an integration platform able to accommodate standard/public and third-party proprietary (Black Box) models and simulations available either as local resources or distributed as enterprise resources. Additionally, we demonstrate our adaptability by seamlessly integrating existing customer tools and products like DOORS® for requirements management and Cameo® for modeling, ensuring a cohesive and efficient engineering workflow. Our approach significantly enhances the management of complex interactions inherent in a systems-of-systems approach. This holistic integration spans the entire engineering lifecycle, fostering efficient analysis, design synthesis, and configuration control. Using PDEF, we pave the way for more effective decision-making and comprehensive solutions across intricate interconnected systems.

Use Case Example: Hypersonic Sensor Track Analysis

Hypersonic Sensor Track Analysis is one example of how we applied digital mission engineering to a complex problem. Digital mission engineering is the use of digital modeling, simulation, and analysis to incorporate the operational environment and evaluate mission outcomes and effectiveness at every phase of the life cycle. Applying a digital mission engineering approach allows the creation of a persistent digital thread that accelerates development and testing throughout the entire product or system life cycle.

This Use Case is characterized by the integration of design reference mission models with executable attributes in a defined architecture that allows coherency between system engineering, operations, and the mission within a given domain. Through our structured engineering process, Parsons develops initial requirements analysis blocks that assesses mission and environment needs, identifies functional requirements, and defines performance and design constraint boundaries resulting in technical requirements repository and the architecture descriptive model. We then continue to allocate performance requirements, define/refine internal and external interface requirements, and decompose to lower-level functions through the development of Use Case diagrams, Sequence diagrams, and Activity Diagrams. Finally, through design synthesis, we transform the architecture from a functional representation to a physical representation where we define alternative system concepts and elements, select preferred product and process solutions, and define physical interfaces resulting in defining mission performance and utility to the warfighter.

Within this digital ecosystem, this process is evolutionary and supports engineering and analysis of the entire system or system-of-systems lifecycle. Digital Mission Engineering provides assurance an intended mission will be achieved. The definition of mission parameters and refinement of requirements are realized thereby reducing uncertainty and increasing confidence in design.

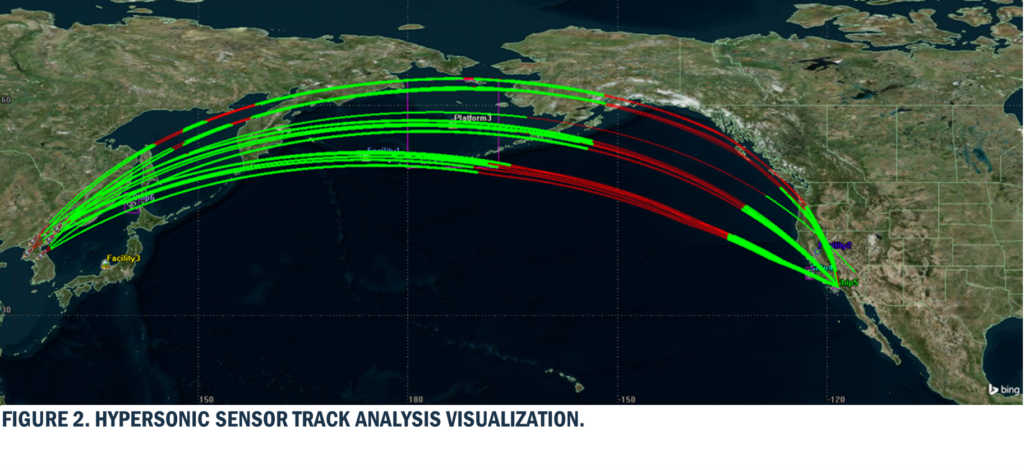

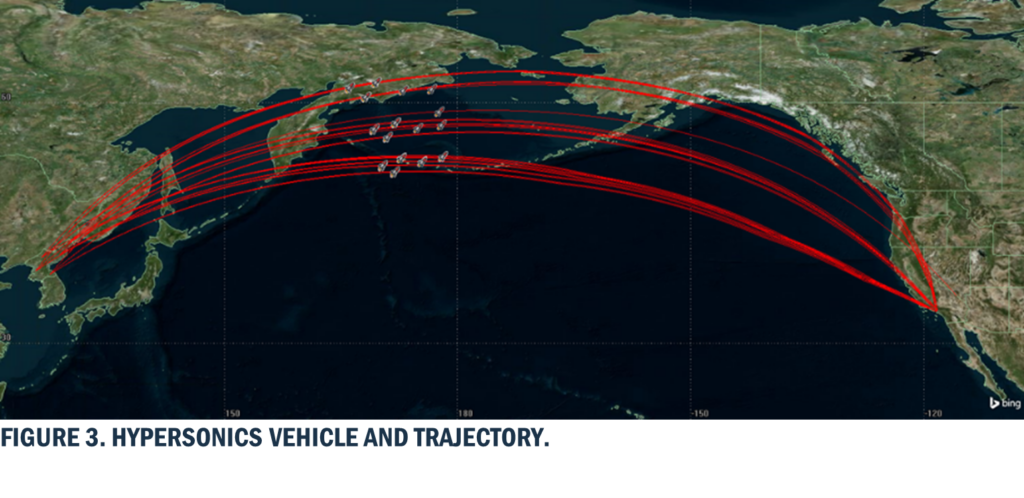

Our PUMA/RTS Team developed a simple MATLAB hypersonic vehicle and trajectory with a constant Angle of Attack (AoA). 50 launch points were generated from North Korea to CONUS (California) with unclassified representative data sets. From a mission perspective, the digital architecture established (hypersonic vehicle, potential trajectories, defended area) could be executed to evaluate the best sensor siting and tracking solutions or even the best missile type and engagement coordinated solutions based on a Warfighter’s mission need statement and emerging threats. From the development of this digital-based representation, we established the means to emulate the capabilities and represent threat thereby enabling full end-to-end evaluation of mission objectives and outcomes. This Use Case establishes the means to develop an architecture, derive requirements, perform and optimization, and probabilistic analysis that can be subsequently evaluated in an MBSE environment.

The MBSE Environment allows requirements trace and Digital Mission Engineering trade-space analytics to be performed. Documenting each and every mission and technical alternative in a digital solution set – an Authoritative Source of Truth (ASoT) as a repository (rather than a written document left open to human interpretation).

Our approach enhances specification development, design quality by developing a coherent model of the system or System of Systems. The “virtual model” becomes the baseline in the ASoT. Document based SE&I relies upon the generation of textual specifications and design documents. Specifications are expressed in documents containing textual descriptions, graphical depictions generated form CAD/drawing tools, and tabular data and plots. Unification of data with an ASoT eliminates the “great paper chase” given the Digital Engineering collaborative environment. With a system model the requirements determination process, Use Cases and interrelationships are inherent and provided the common basis for unified decision analytics. The result is interdisciplinary DE capability to meet design requirements via a M&S process that includes automatic document generation, requirements trace and satisfaction and consistency of data through a central, unified authoritative source. This enables reuse, replication, and redeployment of MBSE models, Digital Twins, Digital Mission Engineering use cases/workflows, facilitates Project Life Cycle (cradle-to-grave) Management and allows a capability to employ graphic notation for understanding internal business procedures (Business Process Management Notation or BPMN).

Parsons Digital Engineering Framework is a paradigm shift beyond conventional modeling methods, embracing a comprehensive integration of diverse tools to not only model systems but to empower decision-making, conduct trade analyses, and establish robust baselines within the realm of Produce Lifecycle Management (PLM). Our tool-agnostic architecture fosters adaptability, enabling government organizations to orchestrate innovation, sound decision-making, and meticulous PLM practices, shaping a future where technology propels innovation and precision and the speed of operations.

Our investment in Digital Engineering has promoted the innovative development of a Model-based, simulation driven capability to perform analysis of complex systems and systems of systems.

The result is Digital Transformation considered, Digital Ecosystem realized, and MBSE implemented for our clients.