Capital Programs And Industrial Manufacturing

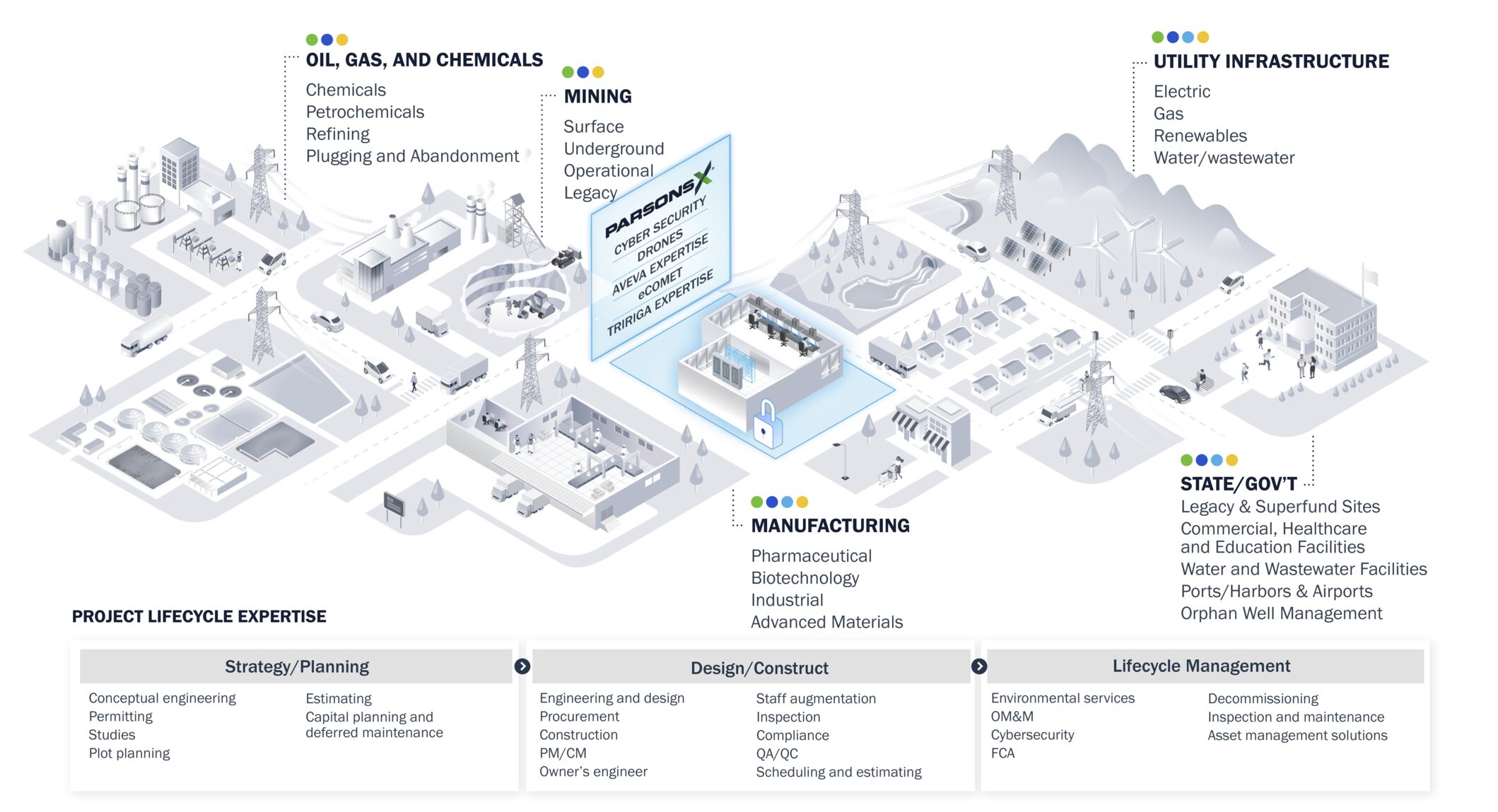

Pharmaceuticals, advanced materials, microelectronics, chemicals and other industrial manufacturing facilities all have something in common — highly complex manufacturing processes. As industries look to “reshore” manufacturing facilities in North America, Parsons can help turn manufacturing facility concepts into reality, delivering complex industrial projects and programs on schedule and within budget.

From energy transition projects, to implementing ultra-pure water systems, or meeting unique capital program requirements, our experts have a proven track record of success in providing industrial manufacturing planning, management, design engineering, and construction management services.

A Broad Spectrum Of Services

Backed by 80 years of global experience, we understand the challenges our clients face when deciding to build, reconfigure, or replace aging facilities. Our integrated program management solutions are designed to ensure that our industrial projects meet the unique needs and requirements of our clients while also being delivered on time and within budget.

Planning and Engineering

- Feasibility studies and site assessments

- Conceptual design

- Capital planning

- Project delivery and contracting strategy

- Front-end and detailed design

- Cold-eyes project cost validation

- Process design evaluation

- Construction engineering

- Facility condition assessment

- Asset lifecycle management

PM/CM Services

- Program and project management

- PMO

- Construction management

- Design management

- Project controls & change/claims management

- Owner’s side support

- Procurement and contract management

- Quality assurance

- Project administration

- Compliance and permitting

- Energy management services

- Industrial wastewater and produced water treatment

- Wastewater management

- PFAs and emerging contaminants

- Water re-use and water reduction

- Energy transition

- Digital twins

- Digital advisory services

- Cyber protection

- Project management information systems (PMIS)

- Data intelligence

- Artificial intelligence and machine learning

- Drone inspections

- Data centers

- Digital engineering

Turning Manufacturing Facility Concepts Into Reality

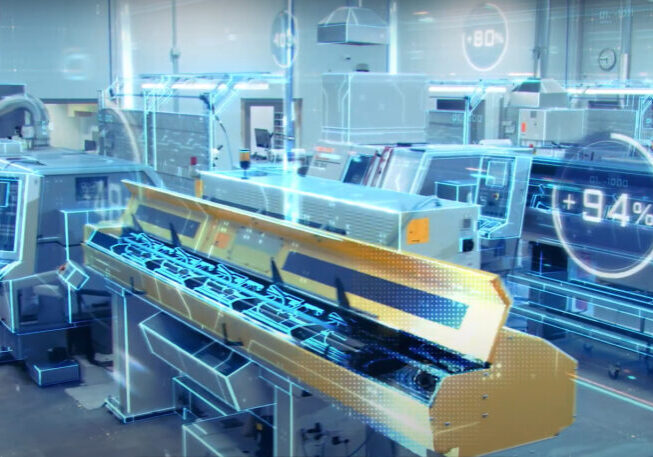

We deliver complex capital program projects, focusing on industrial and reshoring manufacturing, brownfield renovations, expansions, retrofits and mission critical facilities.

Request More InfoFlexible Execution Strategy

Our execution plans are centered on flexibility and responsiveness. We define each client’s requirements at the beginning of the project to plan and execute projects with minimal surprises during the engineering and design work. This proactive process mitigates rework at the later phases of the project, promotes excellent collaboration in the field, and supports a smooth handover and transition from design to construction. We continually adapt our approaches with our client’s teams to ensure a fit-for-purpose, cost-effective engineering package.

Seamless Engineering And Design

Our unified workforce operates with industry-standard engineering procedures and training to provide a fully integrated design, construction, and validation process. As a single-source supplier, we save valuable time while delivering facilities that meet regulatory requirements and incorporate emerging technologies. In addition to our overall design capabilities, we have particular expertise in brownfield renovations, expansions, retrofits, and repurposing of existing assets.

We support all aspects of operations, including:

- R&D laboratories

- Pilot plants

- Process development

- Small and large-scale manufacturing

- Giga plants

- Office, amenity, and warehousing operations

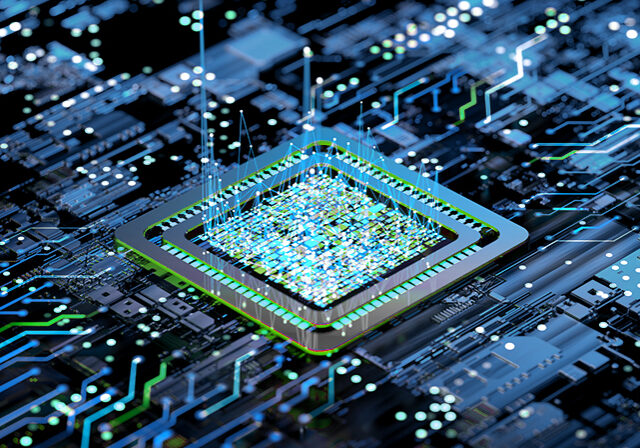

Digital Solutions For Advanced Manufacturing

Complex projects become less so when the right technology is applied. By integrating digital solutions into manufacturing projects, our clients can utilize real-time data for informed decision-making to streamline processes, optimize asset management, reduce costs, and significantly improve delivery and operations.

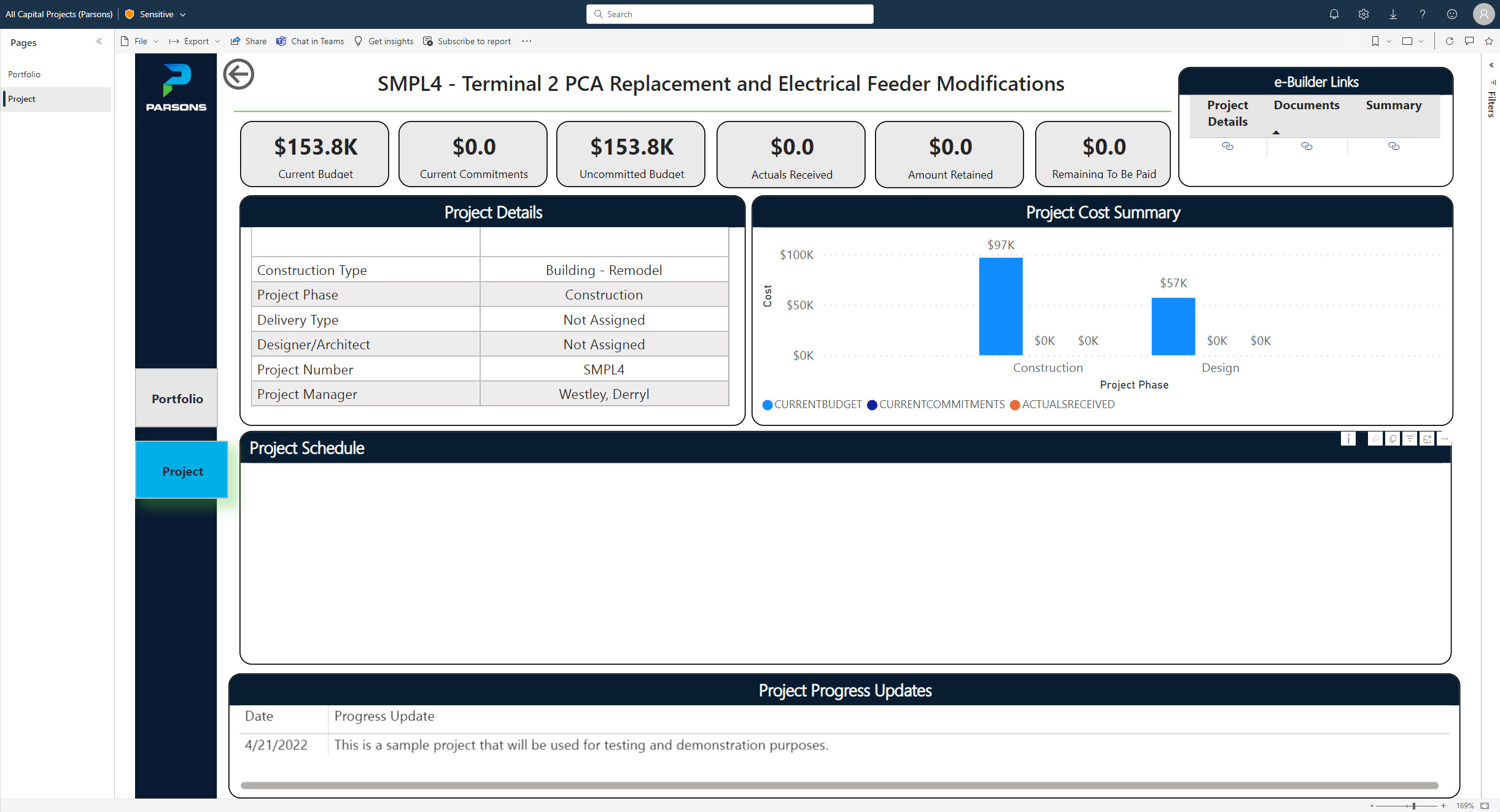

Program Management Information Systems

Our Program Management Information Systems (PMIS) experts guide our customers through their PMIS maturity journey to help break down data silos to synchronize the people, financials, and processes needed to improve delivery and better manage capital projects.

Dashboard Capabilities

Strategic Dashboards And Analytics: Strategic dashboards and analytics are powerful tools that keep the business focused on a common strategic plan. Sitting at the top of the business decision-making spectrum, they are the most strategic level of analysis and help leadership conduct long-term planning and make decisions that impact the organization's trajectory. These tools are primarily used to monitor and control operational execution in alignment with business strategy, ensuring that all efforts are working towards achieving the organization's broader goals.

Management And Operational Dashboards: Management and operational dashboards are valuable tools that provide actionable information in an intuitive format, making it easy for business leaders to understand KPIs and identify areas for improvement quickly. Positioned one level down from the scorecard in the business decision-making process, they are less focused on strategic objectives and more tied to specific goals.

Digital Twins

Our digital twin solutions add value to every phase of the manufacturing lifecycle through three key functionalities: data ingestion and aggregation, advanced analytics, and real-time visualization and monitoring that enables operators to take action. By delivering end-to-end visibility through a single-pane-of-glass, clients can efficiently manage assets and visualize the infrastructure’s operational health to optimize performance, reduce costs, and improve sustainability.

Manufacturing projects involve sensitive data, and manufacturers need to ensure that their systems and networks are secure from potential threats such as cyber-attacks and data breaches.

Our expertise in the design and delivery of infrastructure informs our rapid, interoperable, scalable cyber capabilities. This allows us to protect our clients and their operational technology (OT) systems from cyber-attacks. Our experts work closely with clients to understand their unique needs and challenges and develop tailored solutions to address them. We help manufacturers protect their critical assets and data by leveraging cutting-edge technology and industry best practices, ensuring long-term success and growth.

Our cyber solutions include:

- Assessments

- Vulnerability mitigation planning

- Intrusion detection monitoring

- Incident response planning

Capital Programs Highlights

The Rise Of The Whole Life Partnership Model In The Gulf Region

The whole region has experienced wave after wave of capital investments in infrastructure over recent decades. Arguably, the initial catalyst for this was Dubai, with massive investment reaching a peak […]

Read MoreSupply Chain Security And Assurance For Critical Systems

The supply chain problems plaguing the microelectronics industry predate the COVID-19 pandemic and are due to a culmination of factors. It is increasingly difficult to secure the supply chains of […]

Read MoreParsons Building The Future Of Industrial Cities At OXAGON

CENTREVILLE, Va. (January 31, 2022) – Parsons Corporation (NYSE: PSN) today announced its selection by NEOM Company to provide project management support in building OXAGON – a reimagined industrial city. […]

Read MoreDesigning Tomorrow’s Energy Breakthrough: The National Ignition Facility

Imagine a facility dedicated to cutting edge research that will help keep America safe and secure, while also exploring exciting new frontiers in science and laying the groundwork for a […]

Read MoreNEOM Oxagon

Overview The NEOM region was created by Saudi Arabia’s Public Investment Fund (PIF) as part of the Kingdom’s Vision 2030 to redefine urban living. Parsons was selected by NEOM to […]

Read More