Anacostia River Tunnel Project – District Of Columbia (D.C.)

Client

- District of Columbia Water and Sewer Authority

Project Value

$253,000,000

Market

Energy And Environment, Tunneling, Water And Wastewater

Services

Design And Urban Planning, Engineering, Program/Construction Management (PM/CM)

Our tunnel experts assisted the District of Columbia Water and Sewer Authority (DC Water) with implementing a long-term control plan (LTCP) for the Anacostia River Tunnel and its combined sewer system.

Our Long-Term Control Plan (LTCP)

Our LTCP consisted of a system of tunnels and diversion sewers for capturing combined sewer overflows (CSOs) to Rock Creek and the Anacostia and Potomac Rivers and conveying them for treatment at DC Water’s Blue Plains Advanced Wastewater Treatment Plant. Implemented under a federal consent decree between the United States, the District of Columbia Government, and DC Water, the LTCP was divided into several contract divisions.

The entire project will reduce CSOs by 96% annually throughout the system and by 98% for the Anacostia River alone. The new tunnel segment reduces CSOs to the Anacostia River by more than 80% and holds 40 million gallons of combined sewage.

Services Provided

Division H of the Anacostia River Tunnels was the second tunnel contract of the Clean Rivers Project to begin construction. Work under this contract extended from Robert F. Kennedy Stadium to the Poplar Point Pumping Station in southeast Washington, DC. In a joint venture, we were awarded the Anacostia River Tunnel DC Clean Rivers Project, Division H, Contract 110140 for DC Water. In this design-build team, we were a minor (33%) equity member in the integrated construction joint venture and served as lead designer. The project included:

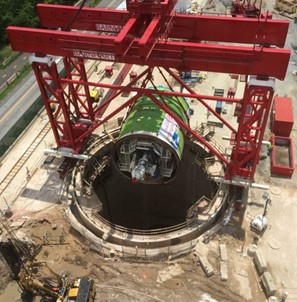

- Design, construction, and commissioning of a 12,300-foot-long, 23-foot-internal diameter tunnel approximately 100 feet underground

- Six 100 feet deep shafts located along the tunnel to serve as access points for the tunnel and to intercept current CSO discharges to the Anacostia River (diameters vary from 19 to 65 feet)

- Construction of five CSO diversion structures and odor control facilities along the tunnel

- Each of the CSOs required permanent tie-ins to existing sewers and temporary bypassing of effluent until the work was complete

- Five vVortex drop shaft hydraulic structures constructed using cast-in-place concrete

- Utility work, consisting of new high-voltage duct banks and isolation switchgear plus relocation and protection of existing utilities along the tunnel alignment

Significant Challenges And Our Solutions

Project Schedule

The project had a challenging schedule due to a federal consent decree. We used an integrated design/construction scheduling approach to ensure design packages were aligned with corresponding construction activities, most effectively managing the critical path and avoiding delays.

Early Tunnel Collapse

An early SEM-excavated tunnel between two shafts at the launch shaft site suffered a collapse early in the project, which delayed the start of TBM mining by approximately 6 months. In order to regain lost schedule so that consent decree deadlines could be achieved, several measures were implemented, such as adding an extra tunnel crew and re-sequencing construction tasks to reduce the duration of other tasks on the critical path. The project was completed within the required schedule.

Federal And Local Government Permitting

The project included extensive permitting by federal and local government agencies. We initiated the permitting process early, jointly reviewing and evaluating proposed permit conditions between the design and construction teams. We successfully suggested alternative conditions that improved the constructability and reduced the construction risk (and project cost/schedule) of the project while addressing regulator concerns.

Added Benefits And Value to Owner

The design team developed a mass concrete mix design that allowed large concrete pours without any heat of hydration issues. This mix was primarily used for shaft base slab pours, which were up to 12 feet thick and 65 feet in diameter poured in a single day. This significantly reduced the time required to build the shafts. All the shafts were excavated “in the dry” with a pressure relief system installed in the granular deposits below the Potomac formation. This allowed higher quality control for construction of the invert slabs and shaft wall to slab connections.

Anacostia Rivel Tunnel Project Joint Venture Team

The integrated design-build joint venture was Impregilo | Healy | Parsons (IHP). Parsons supplied 35% of the project staffing, including key positions such as quality manager, design-build coordinator, deputy project manager, and minority and women’s business enterprise coordinator.

Under subcontract to the IHP Joint Venture, Parsons was the lead designer and filled the key position of design manager and lead engineer. Parsons self-performed over 60% of the design. Construction was substantially complete in 2018.

Learn more about the Anacostia River Tunnel project through DC Water.