Delaware Aqueduct Rondout-West Branch Bypass Tunnel – Newburgh, NY

Client

- New York City Department of Environmental Protection (DEP)

Project Value

$828,408,605

Market

Energy And Environment, Tunneling, Water And Wastewater

Services

Engineering, Program/Construction Management (PM/CM)

We provide comprehensive Construction Management (CM) services for New York City’s Delaware Aqueduct Bypass Tunnel project located in the Mid-Hudson Valley of Lower New York. We have been the CM on the project since construction began in January 2013 and we are now working in our 11th year of this monumental project!

Project Overview

The Delaware Aqueduct, in service since 1944, supplies upwards of 50 percent of New York City’s daily water consumption. The Bypass Tunnel project is designed to replace a leaking portion of the Delaware Aqueduct. The Bypass Tunnel is the most significant, capital construction repair project in the history of New York City’s drinking water supply system.

At 85 miles long, the Delaware Aqueduct is the longest, most active tunnel in the world and a critical component of New York City’s infrastructure.

Our Services

- Planning and Pre-construction Design Evaluation Services which provided basis for the final design which will allow for the safe unwatering of the existing tunnel

- Construction Management of shaft and TBM tunnel construction which resulted in shafts being installed ahead of schedule and under budget

- Environmental Health and Safety

- ISO 9000 Quality Assurance and Quality Control

- Substantial Site Preparation component with suggestions to maintain tunnel spoils on site virtually eliminating offsite trucking

- Close Coordination with NYCDEP Operations to maintain critical NYC infrastructure

- Communication Coordination

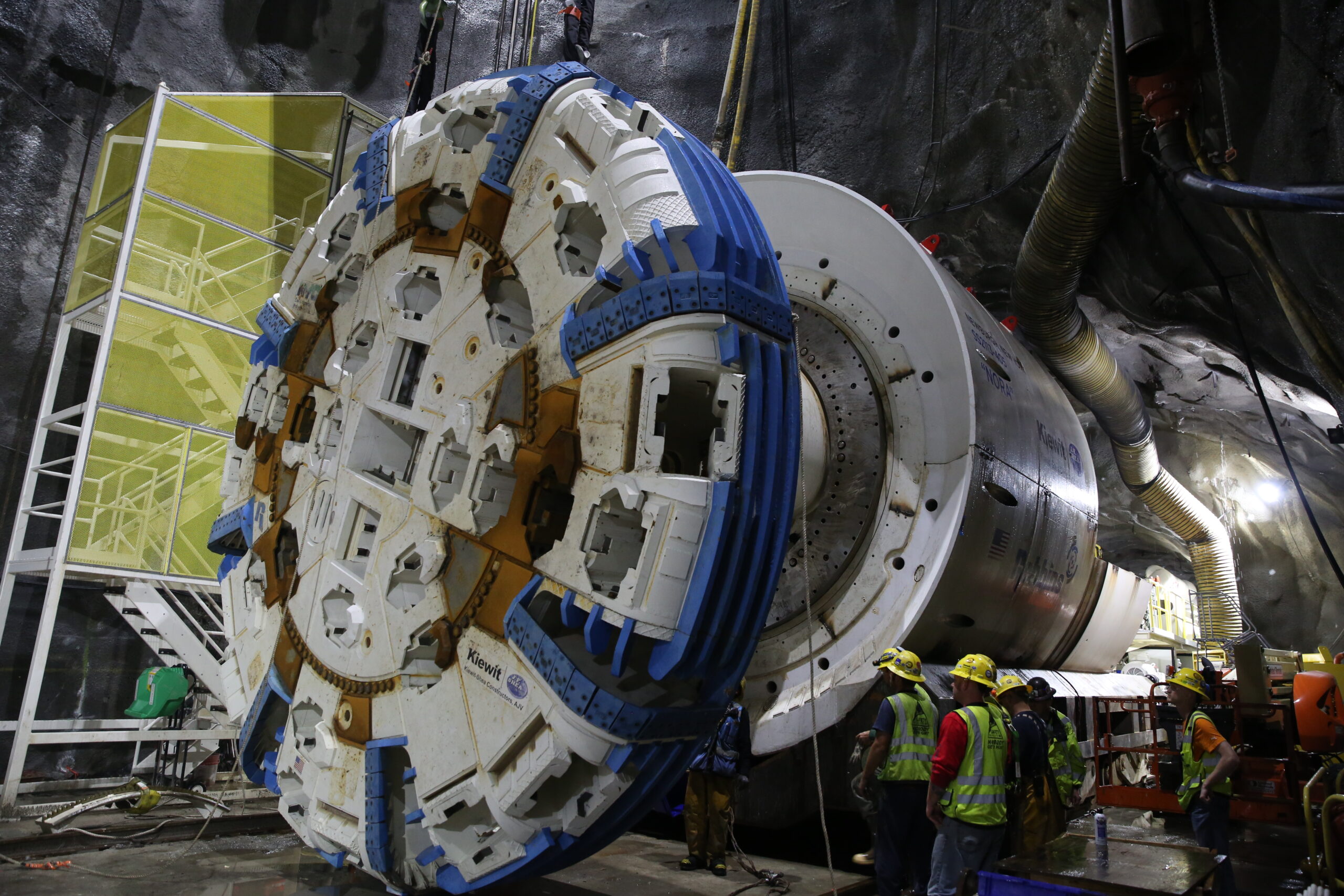

- Nora, the tunnel-boring machine, preparing to go underground.

- The tunnel beginning to take shape.

- Aerial site overview.

- Nora, the tunnel-boring machine used in the project.

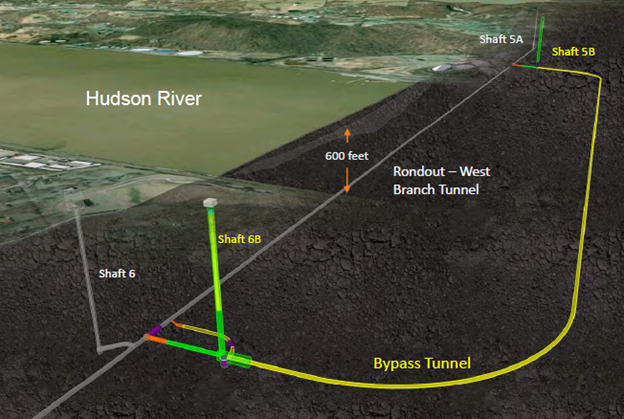

- Map detailing construction plans.

Tunnel Construction: From Shafts To Steel Lining

The initial construction phase included two deep shafts in rock- one 900 feet deep and another 760 feet deep. Once the shafts were completed, more than 1,300 feet of tunnel was excavated by drill and blast techniques, followed by a 12,500-foot-long bored tunnel using a Robbins-manufactured tunnel boring machine (TBM). The TBM bored tunnel was completed in August 2019. The state-of-the-art, hard rock TBM was designed to withstand 30 bars of water pressure as it was mined under the Hudson River through zones of highly permeable and heavily fractured bedrock. Once the TBM bore was completed, a reinforced concrete lining was constructed for the final lining of the tunnel. The final lining included a unique, 1-inch thick, 16-foot diameter solid steel interliner pipe sandwiched between two layers of reinforced concrete to withstand the high water pressure inside and outside the tunnel. The final lining was completed in a ten-step process by November 2021. Once the final lining was completed, two surface structures, known as Shaft Access Chambers, were constructed at the top of each shaft to serve as entry points to the new tunnel and facilitate the connection to the existing active water tunnel. The Access Chambers will allow for future inspection and repair of the tunnels and the possible distribution of drinking water to nearby towns.

Important construction phases were completed in 2022 and 2023, including the Shaft Access Chambers and the large-scale siphon system constructed at the Rondout Reservoir to manage water levels during future storm events. The Access Chambers, siphons, and support systems were completed in December 2022.

The Connection Phase: Challenges And Solutions

Planning this year has centered around the next phase of construction, called The Connection Phase, whereby the Delaware Aqueduct is taken out of service and unwatered to allow the Bypass Tunnel to break into the inactive Delaware Aqueduct and make the new connections on each side of the Hudson River. This year, we performed two pre-connection unwatering exercises to estimate the rate of groundwater infiltration. During the Spring (2023) exercise, the infiltration water flow rate was higher than expected, initiating an unwatering pump augmentation (i.e., upgrade) with two additional vertical turbine pumps (VTPs) to increase the pumping capacity during the connection phase period.

The planning and design tasks were completed this year. Four large-scale drainage pipes will be replaced with larger-diameter pipes to accept the increased water flow. In addition, we had to modify an existing 35-foot diameter by 40-foot tall work deck to carry out the dewatering pump system and installation of the supplemental VTP pumps. The additional VTPs can each pump 15 million gallons of water per day (MGD) and were procured as supplemental pumps under an earlier contract (refer to photos below).

Continuing The Journey

Throughout the Delaware Aqueduct, 2023 unwatering events (each exercise went 24 hours a day, seven days a week for four weeks, Parsons CM provided oversight, data collection, and consultation during the critical planning exercise. The subsequent pump system upgrade and planning phase this year included several workshops and work plan development to secure the next phase of work, scheduled to begin in the Summer of 2024. We plan to start the contract for the Connection of the Bypass Tunnel to the Delaware Aqueduct in October 2024.

Quick Project Facts

- Largest and most complex repair project in the 180-year history of NYC’s municipal water supply

- The Delaware Aqueduct Rondout-West Branch Bypass Tunnel (RWBBT) project will replace a portion of the 45-mile Rondout/West Branch tunnel section of the Delaware Aqueduct that connects the Rondout Reservoir in Ulster County to the West Branch Reservoir in Putnam County

- Building and connecting a new 2.5-milelong, steel and concrete lined bypass tunnel, 600 feet below the Hudson River from Newburgh to Wappinger Falls NY. Two 30-foot diameter shafts with a 20 MGD dewatering pump station.

- Will eliminate the 15- to 30-mgd leak from the existing 80 year old, 13.5 foot diameter tunnel that conveys approximately 50-60 percent of NYC drinking water from the Catskill Watershed

- The last phase of repairs are scheduled to start in October of 2024.

Project Awards And Accolades

- We received the DEP BEDC 2017 Award for “outstanding performance on the EHS Management System Audits and Implementation of Best Management Practices for Program Efficiency, Risk Control and EHS Culture

- We received an Excellence Award in Construction Management from the NYCDEP in 2017. Our team developed a unique approach to connect the new tunnel to the existing tunnel, reducing time of the shutdown tunnel outage from 16 months to six months.