Pump Stations Improvements Project — Redwood City, CA

Client

- Silicon Valley Clean Water (SVCW)

Project Value

$105 million

Market

Water And Wastewater

Services

Design And Urban Planning

The SVCW conveyance system transports raw wastewater from its member agencies to the Wastewater Treatment Plant (WWTP) and four satellite pump stations that convey flow to the SVCW WWTP through a conveyance system force main. When the pump stations and force mains had reached the end of their useful lives and did not meet the 2030 projected flows, SVCW undertook a series of improvement projects, titled the Regional Environmental Sewer Conveyance Upgrade (RESCU) program. The program provided a new pump station and headworks at the WWTP, a new 3.5-mile, 11-foot-diameter gravity pipeline, and rehabilitation and repurposing of satellite pump stations.

This project’s scope of work included the design and construction of two rehabilitated pump stations, one new pump station, and a new pipeline. This project rehabilitates or replaces nearly all components of the existing conveyance system, including pipelines and pump stations on three separate sites within member agency cities: the Menlo Park Pump Station (MPPS), the Belmont Pump Station (BPS), and the Redwood City Pump Station (RCPS).

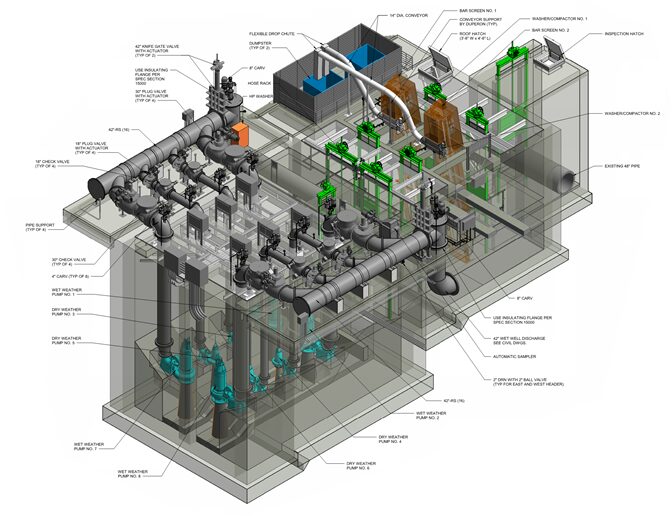

- 3-D rendering of the Redwood City Pump Station

- Redwood City Pump Station in operation

- 3-D rendering of the Menlo Park Pump Station

Design/Preconstruction Services

Parsons served as Lead Designer, responsible for all design services provided on the project, including the development and implementation of the SCADA and local control systems design for the project. This included defining system requirements, integrating the system into the facility’s existing control and SCADA systems, and associated testing and validation.

Parsons’ Design and Construction Team members participated throughout the preconstruction phase of the project in developing and implementing innovations that reduced project risks and costs, improved facility operability and maintainability, and delivered schedule savings.

Innovation And Value Engineering

The conceptual design prepared by the Owner’s Engineer included the design/construction of one new pump station and rehabilitation of two existing pump stations. During the preconstruction phase, the Parsons design/construction team evaluated the possibility of eliminating one of the pump stations and replacing it with a gravity pipeline. This innovation eliminated significant long-term O&M costs while simplifying the sewer system’s overall operation. To minimize impacts to traffic and the general public in the vicinity of the new pipeline, the pipeline was installed using trenchless technologies.

Construction Services

The project was executed as an element of the SVCW RESCU Program, which comprised three major contracts. Each of these contracts had interface points between each other and plant Operations and Maintenance (O&M) activities, while also sharing space at the plant site. As a joint venture member of two of the three RESCU project contracts, Parsons staff were actively involved in inter-project coordination to avoid delays and impacts between the contracts and plant operations. The joint venture self-performed approximately 65% of the project scope, including structural, mechanical, civil, and startup and commissioning related components of the project.

- Early Works Packages

To accelerate the project’s critical path, the project used multiple Guaranteed Maximum Price (GMP), enabling construction to begin early on key activities. This accelerated the start of construction by several months. To reduce contingency associated with the project’s electrical scope, a separate GMP was established for the electrical work following completion of additional design, eliminating significant contingency from the electrical GMP.

- Risk And Opportunity Management

During the design development and construction planning phase of the project, the project team developed a risk and opportunity matrix that was used to establish project contingency values. During the construction phase, this risk and opportunity matrix is frequently updated to the latest project status to enable accurate projection of the project’s final construction cost and remaining risk exposure.

Collaboration

A project cost model and schedule were developed at the start of the preconstruction phase. These were used in the evaluation of design/construction innovations, constructability improvements and scope changes, through collaboration with SVCW and the use of “design to budget” principles. These principles leverage the value of the open book pricing approach by providing greater transparency to better inform decision-making related to potential scope changes. The application of design to budget principles facilitated a GMP that was within 1.3% of the initial cost estimate prepared by the joint venture.